Description:

Closed-Cell High Density Polystyrene Foam

The InSoFast panels are made up of a fire-retardant foam. This type of foam is rated for below grade applications and does not absorb moisture like the open-cell type of bead board.

InSoFast is a Type III Vapor barrier and is inherently mold resistant. This type of foam is the perfect insulating material for basements.

Embedded Polypropylene Attachment Studs

The InSoFast attachment studs are made of 100% recycled polypropylene. This material has low thermal conductivity yet has extremely high strength characteristics.

These studs will never mold or rot and they will not bow or twist, leaving a straight, stable surface for drywall or exterior finishes attachment.

ISF Wall

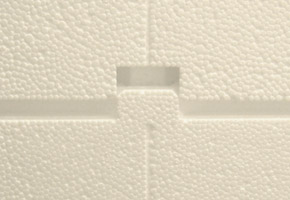

Alignment Notches

A unique self-aligning notch system is designed into the InSoFast panels to assure that the panels are installed on the concrete surface in alignment. This keeps the studs and wiring chases aligned.

Alignment Notches

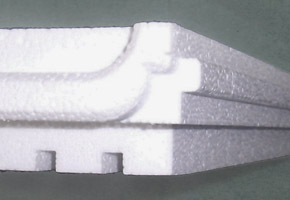

Tongue & Groove Edges

The tongue-and-groove design on the ends of the InSoFast panel help to keep the panels flush on the surface. They are also flashed in such a way as to keep water from traveling to the front side of the panel.

Wiring Chases

Wiring Chases run vertically at 16" on center and horizontally at 24" on center in the panels. This grid work of chases provide easy access to pull wiring to any location.

The chases also provide the necessary separation from the drywall face to protect the wiring as required by electrical codes.

Ribbed Gluing Surface

Each InSoFast panel has three attachment studs with a ribbed surface to allow the adhesive to maintain a tight adhesion to the wall.

The studs can be located with a stud sensor.

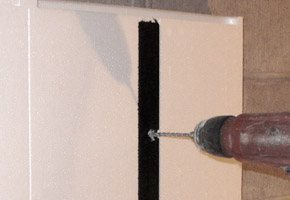

Recessed Attachment Points

The three recessed attachment points on the face of the integrated stud allow for any mechanical fastening that may be needed. Because these attachment points are recessed, hex head masonry screws can be used.

Technical Specification:

InSoFast is a closed-cell expanded high density polystyrene panel with three integrated polypropylene attachment studs. The tongue-and-groove edge design provides secure connection between panels. The panel is 48" x 24" x 2" thick.

Moisture Drainage: The back side of the InSoFast panel is ribbed to provide moisture drainage channels but is not classified as a water proofing material.

Wiring Chases: Chases are located 1-1/2" below the surface of the panel and spaced 16" o.c. vertically and 24" o.c. horizontally (National Electric Code - NEC Article 330-4d and 300-41a).

Attachment Studs: Attachment Studs provide solid attachment for drywall. They have no nutrient value to animals, insects, or micro-organisms. There is no nutrient value for bacterial growth, including mold. Polypropylene attachment stud (ASTM D 1929, ASTM D 635, ASTM D 2843, ASTM D 638).

EPS (Expanded Polystyrene): InSoFast is shape molded at 1.25 pcf with Type VIII - Flame Retardant Expanded Polystyrene. EPS is a moisture resistant closed-cell foam which contains no ozone depleting CFCs or HCFCs and is 100% recyclable. No toxins or formaldehydes are produced. EPS is inert and experiences no physical or chemical breakdown over time. There is no nutrient value to animals, insects, bacteria, or mold.

Usage:

InSoFast is a non-structural panel installed on masonry block or poured concrete surfaces. The masonry block and concrete surfaces must be structurally sound. The InSoFast panel is bonded to the masonry block or concrete surface with construction adhesive as per manufacturer's recommendations.

Construction Note: In most installations, InSoFast panels must be covered with a 15 minute thermal barrier (typically 1/2" drywall) or otherwise installed in accordance with applicable building code requirements.

InSoFast Pull Out, Pull Off, and Shear Report

|

ASTM D1761-06 “ Standard Test for fastener Shear and Pullout”

The average ultimate fastener withdrawal is 211 pounds for the #6 coarse thread screw. The design load incorporating safety factor per ICC-ES AC116 is 42.2 pounds per fastener.

The average ultimate fastener “shear” or lateral load was 403 pounds for the #6 coarse thread screw. Design load incorporating safety factor per ICC-ES AC116 is 100.75

|

| InSoFast R-Value Report |

| InSoFast Panel per Inch |

R4.45 |

| InSoFast Panel |

R8.50 |

| InSoFast Panel over CMU Wall / Drywall |

R11 |

| InSoFast Panel over Concrete Wall/Drywall |

R10 |

|